Support hotline

400-810-0881

bioreactor

The Sartorius Group was founded in 1870 and is headquartered in Göttingen, Germany, with more than 5,000 employees worldwide. The Sartorius Group is a leading international provider of laboratory instruments, biopharmaceutical technology and equipment, providing bioprocesses, laboratory products and services, and industrial weighing products.

Sartorius is committed to providing Chinese customers with state-of-the-art laboratory instruments such as laboratory balances, pipettes and pure water equipment, laboratory consumables including laboratory filters and pipette tips, and superior service. Its bioprocess solutions cover filtration, liquid handling, fermentation, cell culture and purification, and are dedicated to process control in the biopharmaceutical industry, providing cutting-edge equipment and complete solutions for biopharmaceutical development, quality control and production processes. Laboratory Products and Services mainly produces laboratory instruments and consumables. Industrial weighing focuses on weighing, monitoring and controlling production rocesses in the food, chemical and pharmaceutical industries.

Beijing Zhongyuan Ltd. is an important partner of Sartorius in the field of bio-pharmaceuticals. It assists Sartorius in introducing its advanced technologies and products to the vast number of biopharmaceutical users in China, and contributing to the development and progress of biopharmaceuticals in China.

1、aseptic pipe machine

BioWelder® Aseptic Piper - Fully Automatic Hose Assembler

BioWelder® can be used to interconnect thermoplastic hoses on disposable bag systems, and the two hoses are individually inserted into the tube holders, which are cut by the blades and fused together. The blade remains sterile and pyrogen free throughout the operation. In this way, sterile connections can be easily achieved in a non-sterile environment. The tube holders are available in a variety of sizes from 1/4" to 3/4". The unit uses integrated circuit chips to identify tube holders of each size, ensuring high quality hose connections.minimize the risk of operational errors.

• Housing: stainless steel

• Interface: Printer Interface RS232

• Blade: Nichrome, single use

• Temperature sensor: K type with calibration bracket

• Tube outer diameter maximum: 3/4", tube outer diameter minimum 1/4"

• Welding cycle: 60-90 seconds, depending on pipe diameter

• Suitable piping: C-Flex®, PHARMED® BPT, Sanipure® 60Advantaflex®, FluiSoft®

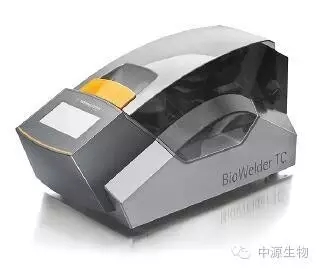

BioWelder® Total Containment Sterile Pipe Receiver

———The large size filled liquid pipeline automatic aseptic welding device

BioWelder® TC can be used to interconnect thermoplastic hoses on disposable bag systems, and both in clean and non-clean areas, the BioWelder® TC provides an aseptic connection to empty lines or filled with liquid lines. Place the tube holder, hose, and blade into the BioWelder® TC, the touchpad is activated, and the tubing connections are automatically completed. The infrared sensor controls the temperature of the blade throughout the connection process. The blade heats up to the heat source, then cools to the soldering temperature, cuts the hose and connects. Tube holders are available in a variety of sizes from 3/8" ID x 5/8" OD to 3/4" ID x 1" OD. BioWelder® TC automatically recognizes specifications and ensures high quality tubing connections. The risk of mistakes is minimized.

• Temperature sensor: K type with calibration bracket

• Tube holder specifications: 3/8" ID×5/8" OD, 1/2" ID×3/4" OD, 5/8" ID×7/8" OD, 3/4" ID×1" OD

• Connection period: 1 minute 30 seconds - 2 minutes 30 seconds

• Suitable piping: C-Flex®, PharmaPure®, AdvantaFlex®, PharMed® BPT, SaniPureTM BDFTM

• Minimum hose: length 450mm

• Maximum operating pressure: 1 bar

2、 aseptic sealing machine

BioSealer® Sterile Tube Sealer - for permanent and reliable thermoplastic hose seals

BioSealer® is primarily used to safely separate the thermoplastic hose from the disposable bag system from the system. BioSealer®'s two ceramic heating elements compress and heat the tubing placed in it, and the high temperature and pressure fuse the tubing into a homogeneous section, which can be cut with sharp scissors. The unit can be used for the sealing of thermoplastic hoses with 1/4"- 3/4" OD and is ideal for use with single-use sterile reservoir technology. BioSealer® has a choice of mobile sealing heads. The sealing head can be used up to 3 meters away from the mainframe, making it easy to adapt to various space requirements.

• Housing: stainless steel

• Extrusion head: aluminum (anod plating)

• Maximum tube outer diameter: 3/4", minimum tube outer diameter: 1/4"

• Sealing cycle: 1-4 minutes, depending on hose size and material

• Hose type: thermoplastic hoses (eg C-Flex®, Advantaflex®, SaniPure® 60, FluiSoft® and Pharmed® BPT)

3、Controllable freezing and thawing system

Celsius® S3 Laboratory Controlled Freeze-Thaw System

The Celsius® S3 system is the only small-capacity controlled freeze-thaw system that can be scaled up to production scale using single-use containers. This system allows the development and stability of freeze-thaw processes with minimal amounts of product. The Cryopilot control unit enables automatic operation and data acquisition. The Celsius® S3 system can freeze or thaw 1-10 samples per run. The Celsius®-Paks sterile freeze-thaw bags are available in 30ml and 100ml. The Celsius® S3 system provides excellent reproducibility between batches and maintains stability after freezing, thawing and storage.

• Scale up, scale down

• Stability research, research and development

• 302/304 stainless steel housing: high cleanliness

• Low temperature agitator PVC cover

• Heat Transfer Fluid (HTF) Dow High Temperature Heat Transfer Oil

• Temperature range: rated temperature: +40 ° C to -70 ° C

Celsius® FT100 Modular Controllable Freeze-Thaw System

The Celsius® FT100 modular freeze-thaw system controls the freezing and thawing process while minimizing the adverse effects on biopharmaceutical products. A powerful and reliable modular freeze-thaw system platform with a single-use Celsius®-Paks freeze-thaw bag that can handle up to 100 L of solution at the same time.

• System equipped: freeze-thaw module supporting Celsius®-Paks, temperature control unit, control panel.

• Main features: pre-sterilized, disposable closed system; simplified operation; can be amplified; reliable and durable; complete logistics solution; meet GMP requirements.

• FT freeze-thaw module, smart device, ergonomic design for maximum flexibility

• The basic FT module (Celsius® FT33) can expand up to two additional modules

• Heat exchanger plates are installed on each module, and the inside of the heat exchanger plates is temperature controlled by liquid circulation

• Each Celsius® FT100 module has a docking locator aligned to the transport or storage module to simplify transport between Celsius®-Paks and Celsius® FT100 freeze-thaw modules

• Temperature Control Unit (TCU) for powerful and repeatable freezing and thawing cycles

• Available in 2 sizes of TCUs based on the number of freeze-thaw modules

• TCU 620 for single modules

• TCU 630 for 2 or 3 modules

• Based on pre-set parameters, the TCU temperature control unit controls the freeze-thaw process by monitoring the temperature and flow rate of the heat transfer fluid

• Simple, user-friendly, and secure controller:

• The controller is connected to the temperature control unit and the FT freeze-thaw module via Profinet

• Human Machine Interface (HMI) connects the touch screen computer to the Siemens PLC

• Important parameters in all operations are fully automated for command release, process monitoring and record storage, minimizing operator monitoring

• Software meets 21 CFR Part 11, traceability review

4、automatic dosing platform

FlexAct BP│MP Automatic Dosing Platform - Buffer │ Medium Automated Sterile Solution

The FlexAct BP│MP system is a standardized, optional, single-use solution for buffering media in biopharmaceutical processes. The FlexAct BP│MP system can be used to configure the entire process of 50L-1000L buffer solution. The system integrates pH, pump speed and level monitoring and control functions, and the design is a milestone for the integration of process-related disposable equipment. These integrated control functions allow the operator to perform some other work while performing buffer │ media configuration operations. The Flexel® aseptic reservoir is combined with the Magnetic Mixer® mixing system and multiple Palletank®, and the multi-function central control module allows the customer to install, operate and monitor the single-use unit in the Buffer® media configuration.

Features:

• Multi-function central control module

• Configuration of multiple liquid handling bags

• Buffer │ medium configuration volume range: 50L-1000L

• The system quickly builds integrated, single-use sensors

• Two-way operation

Advantage:

• Friendly interface

• Flexible buffer │ medium supply

• Zoom in

• Effective equipment utilization

• Process real-time monitoring

• Highly flexible

Zhongyuan Bio is an authorized agent of Sartorius

If you have any questions, please call the toll-free service number:

400-8100-881

If you have any comments or suggestions on our services, please send them to the following email address:

Service@sinozhongyuan.com

京公网安备11010502040370号 Technical Support:Qingyun Software

京公网安备11010502040370号 Technical Support:Qingyun Software